Safety

Carpentry, Ceilings and Metal Framing

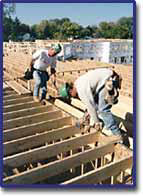

Carpenters

work in many different areas of the construction industry. The need for

carpenters is greatest in the field of new construction, but many carpenters

also work on modifying existing structures or remodeling projects. Carpentry

is a year round occupation that requires skill with wood materials, metal

framing, flooring, lath and other fabrication techniques. The Joint Brotherhood

of Carpenters and Joiners offers a four year apprentice training program

to those who wish to enter the carpentry trade.

Carpenters

work in many different areas of the construction industry. The need for

carpenters is greatest in the field of new construction, but many carpenters

also work on modifying existing structures or remodeling projects. Carpentry

is a year round occupation that requires skill with wood materials, metal

framing, flooring, lath and other fabrication techniques. The Joint Brotherhood

of Carpenters and Joiners offers a four year apprentice training program

to those who wish to enter the carpentry trade.

Carpenters

use subflooring, sheathing, floor joists, studs and rafters to assemble

a building. Carpenters also install heavy timbers, build forms for concrete,

erect scaffolding and install floor coverings. Finish work including the

installation of molding, wood paneling, cabinets, window sashes, door

frames, doors and hardware is all done by carpenters. Carpenters build

stairs and lay floors, cut and fit plywood, wallboard and other materials.

Carpenters

use subflooring, sheathing, floor joists, studs and rafters to assemble

a building. Carpenters also install heavy timbers, build forms for concrete,

erect scaffolding and install floor coverings. Finish work including the

installation of molding, wood paneling, cabinets, window sashes, door

frames, doors and hardware is all done by carpenters. Carpenters build

stairs and lay floors, cut and fit plywood, wallboard and other materials.

Carpenters need strong mathematics

skills, good mechanical aptitude, physical strength and agility. They

work with both hand and power tools and need to be skilled in the use

of measuring tools and blueprint reading. The opportunities for journeymen

carpenters are as varied as the buildings they help to erect.

Millmen produce custom millwork

for specialty applications and other architectural details from all types

of materials for new and restoration work. Millmen fabricate cabinets,

shelving, and wood trim including base molding and crown moldings. Millmen

also install cabinet doors and hardware. Millmen produce fixtures and

cabinets for permanent commercial installation, such as those used in

hospitals, offices, hotels, motels, restaurants and mercantile establishments.

Back to Top

Executing

the unique interior design details conceived by the architect or other

design professional is the main function of wall and ceiling tradesmen.

Wall and ceiling craftsmen often erect and finish interior and exterior

sides of curtain walls on commercial and institutional buildings. Then,

working with a wide variety of commonand sometimes exoticbuilding materials,

these craftsmen subdivide the open floor area of a newly erected, unfinished

building into offices, work areas, hallways, restaurants, restrooms, lobbies,

and any other conceivable interior work or living space. Once the heating,

plumbing, electrical and mechanical systems are in place, the ceiling

work can be completed.

Executing

the unique interior design details conceived by the architect or other

design professional is the main function of wall and ceiling tradesmen.

Wall and ceiling craftsmen often erect and finish interior and exterior

sides of curtain walls on commercial and institutional buildings. Then,

working with a wide variety of commonand sometimes exoticbuilding materials,

these craftsmen subdivide the open floor area of a newly erected, unfinished

building into offices, work areas, hallways, restaurants, restrooms, lobbies,

and any other conceivable interior work or living space. Once the heating,

plumbing, electrical and mechanical systems are in place, the ceiling

work can be completed.

Interior

walls are generally constructed of cold-formed steel framing and various

types of gypsum board. However, clean areas such as commercial kitchens

and health care facilities require more durable wall materials. Some of

the new abuse and impact resistant gypsum board or cement board materials

fill this need. Veneer plaster over “blueboard” is used in other situations

where impact resistant walls are required-, as is metal lath and three-coat

plaster.

Interior

walls are generally constructed of cold-formed steel framing and various

types of gypsum board. However, clean areas such as commercial kitchens

and health care facilities require more durable wall materials. Some of

the new abuse and impact resistant gypsum board or cement board materials

fill this need. Veneer plaster over “blueboard” is used in other situations

where impact resistant walls are required-, as is metal lath and three-coat

plaster.

Ceilings in most modern buildings are generally constructed of drywall, plaster or one of the many types of suspended ceiling tile systems. Metal Suspension ceilings are hung from the structural steel above the ceiling. A wide selection of acoustical and light reflecting features is available in an economical suspended ceiling. Accessibility to mechanical, electrical and plumbing systems is one of the benefits of suspended ceiling systems.

To properly do the job, wall

and ceiling tradesmen need a thorough understanding of the materials,

techniques and tools used in their trade. This means having strong mathematical

skills; having the ability to properly use both hand and power tools,

laser levels, and other sophisticated measuring tools; having the ability

to read blueprints and other construction documents.

Back to Top

Drywall

finishers are important members of the interior finishing team. The drywall

finisher ensures that all seams, angles, corner beads and nail spots are

finished and sanded smooth. Finish work around critical lighting and architectural

designs are areas where unique techniques are used for reducing expansion,

crowning, ridging and beveling edges of walls and ceilings. This is necessary

in creating a unified and seamless wall or ceiling surface to which paint,

wallcoverings or other decorative finishes can be properly applied.

Drywall

finishers are important members of the interior finishing team. The drywall

finisher ensures that all seams, angles, corner beads and nail spots are

finished and sanded smooth. Finish work around critical lighting and architectural

designs are areas where unique techniques are used for reducing expansion,

crowning, ridging and beveling edges of walls and ceilings. This is necessary

in creating a unified and seamless wall or ceiling surface to which paint,

wallcoverings or other decorative finishes can be properly applied.

The

finish work done by drywall tradesmen is accomplished with various hand

finishing techniques. Fire-taping, sanding, screw and nail spotting are

a few of the specialized techniques used to finish drywall in the commercial

and institutional building environment. Drywall finishers also use joint

treatment material to finish metal trim and corner beads. The drywall

finisher uses different types of tape and specialized sand-paper designed

for both wet and dry sanding. Sanding is done either with a pad, block

or a “pole-sander.” Joint treatment compounds are applied with drywall

tape to seal the joints between sheets of drywall material. Application

of compounds and tape can be done either by hand or “bazooka.” The bazooka

is a specialized drywall tool that applies both tape and joint treatment

compound in one application. The bazooka saves both time and money and

many contractors choose this method over hand application of joint compound

and tape.

The

finish work done by drywall tradesmen is accomplished with various hand

finishing techniques. Fire-taping, sanding, screw and nail spotting are

a few of the specialized techniques used to finish drywall in the commercial

and institutional building environment. Drywall finishers also use joint

treatment material to finish metal trim and corner beads. The drywall

finisher uses different types of tape and specialized sand-paper designed

for both wet and dry sanding. Sanding is done either with a pad, block

or a “pole-sander.” Joint treatment compounds are applied with drywall

tape to seal the joints between sheets of drywall material. Application

of compounds and tape can be done either by hand or “bazooka.” The bazooka

is a specialized drywall tool that applies both tape and joint treatment

compound in one application. The bazooka saves both time and money and

many contractors choose this method over hand application of joint compound

and tape.

Drywall finisher apprentices

are trained in a two-year apprentice program taught at the Painting and

Drywall School in Hazel Park, Michigan. Those in the drywall trade must

be especially aware of safety due to their frequent use of ladders and

scaffolding, as well as often working in confined spaces. The ability

to read blueprints, good mathematics aptitude and mastery of the architect’s

scale, as well as knowledge of the care and maintenance of the specialized

equipment used in the trade, are all part of the skill and artistry of

a successful drywall tradesmen.

Back to Top

Lathing

is a branch of carpenter trade. Lathers work with the metal components

of a building's structure including black iron, cold formed steel framing,

and metal lath. Lathing is the foundation or metal framework over which

wet plaster or Exterior Insulation Ffinishing System (EIFS) materials

are often applied. Floors in computer rooms that allow cables to run under

removable floor panels, wall partitions and office furniture systems are

some of the unique elements the Lathers are responsible for installing.

Spray applied fire proofing materials are also occasionally applied over

metal lath when the condition of the substrate prevents the direct application

of the spray applied fire proofing materials . Lathers are responsible

for the constructing and installing of all light iron construction, furring;

making and erecting of brackets, clips, and hangers out of wood, wire

or metal lath. In addition, the lather is responsible for the nailing,

tying and fastening of wire and metallic lath and the placing of hangers

that support suspended ceilings.

Lathing

is a branch of carpenter trade. Lathers work with the metal components

of a building's structure including black iron, cold formed steel framing,

and metal lath. Lathing is the foundation or metal framework over which

wet plaster or Exterior Insulation Ffinishing System (EIFS) materials

are often applied. Floors in computer rooms that allow cables to run under

removable floor panels, wall partitions and office furniture systems are

some of the unique elements the Lathers are responsible for installing.

Spray applied fire proofing materials are also occasionally applied over

metal lath when the condition of the substrate prevents the direct application

of the spray applied fire proofing materials . Lathers are responsible

for the constructing and installing of all light iron construction, furring;

making and erecting of brackets, clips, and hangers out of wood, wire

or metal lath. In addition, the lather is responsible for the nailing,

tying and fastening of wire and metallic lath and the placing of hangers

that support suspended ceilings.

Lathers

not only work with wall and ceiling construction, but also work with all

types of floor lath. Lathers learn their trade at The Carpenter’s Apprentice

School and on the job as apprentices. Lathers need to be skilled in light

gauge welding, the use of the builder’s level and transit, roof framing,

cold formed steel framing, drywall installation, demountable partitions,

advanced math, interior trim installation, stair building and blueprint

reading. They must attend the Carpenters Apprentice School for four years

before achieving journeyman status.

Lathers

not only work with wall and ceiling construction, but also work with all

types of floor lath. Lathers learn their trade at The Carpenter’s Apprentice

School and on the job as apprentices. Lathers need to be skilled in light

gauge welding, the use of the builder’s level and transit, roof framing,

cold formed steel framing, drywall installation, demountable partitions,

advanced math, interior trim installation, stair building and blueprint

reading. They must attend the Carpenters Apprentice School for four years

before achieving journeyman status.

Back to Top

The

scope of the plasterer’s work is quite diverse. The wide range of projects

a plasterer might work on can range from the intricate coves and soffits

in a cathedral to the clean lines and geo-metric details of a shopping

mall or school gymnasium. Plasterers typically apply gypsum plaster to

some type of lath or an interior masonry substrate, install exterior insulation

finish systems (EIFS), apply stucco to exterior walls and ceilings, and

install or spray-on soundproofing and fireproofing in buildings.

The

scope of the plasterer’s work is quite diverse. The wide range of projects

a plasterer might work on can range from the intricate coves and soffits

in a cathedral to the clean lines and geo-metric details of a shopping

mall or school gymnasium. Plasterers typically apply gypsum plaster to

some type of lath or an interior masonry substrate, install exterior insulation

finish systems (EIFS), apply stucco to exterior walls and ceilings, and

install or spray-on soundproofing and fireproofing in buildings.

In a typical plaster application, the surface must first be prepared to receive a plaster finish. This often requires the installation of one of several types of metal lath, or gypsum lath or the substrate may be bare masonry. The plasterer then applies plaster, stucco or cement with hawk and trowel or mortar pump over the substrate. The skilled hand of the plasterer may then add intricate and often complex design details to a surface that imparts a hand crafted quality to a project. Skills such as wall and ceiling layout and blueprint reading help the master plaster tradesmen translate the deign details in blueprints and shop drawings into permanent works of art for generations to come.

Plaster

is used widely in restorations, and many new construction projects integrate

plaster with newer technologies. Plasterers create specialized molds used

to cast detailed decorative designs or moldings that are then applied

to a ceiling or wall surfaces adding stylized design elements to the interior

surfaces of the structure. These castings, along with new wet-applied

moldings, are used in the restoration of theatres, churches and older

buildings to return them to their original opulence.

Plaster

is used widely in restorations, and many new construction projects integrate

plaster with newer technologies. Plasterers create specialized molds used

to cast detailed decorative designs or moldings that are then applied

to a ceiling or wall surfaces adding stylized design elements to the interior

surfaces of the structure. These castings, along with new wet-applied

moldings, are used in the restoration of theatres, churches and older

buildings to return them to their original opulence.

EIFS is one of the most widely

used new materials applied by plasterers. Used in both new construction

and renovation, EIFS is a system that incorporates rigid expanded polystyrene

insulation with specially formulated basecoats, fiberglas mesh reinforcement

and acrylic finishes, to provide a wall system, which is both thermally

efficient and aesthetically appealing. The wide variety of colors and

textures, skillfully applied by trained, experienced tradesmen, offers

design flexibility, which is unsurpassed in the in the industry today.

Back to Top

The

installation of carpeting, hardwood flooring and resilient flooring made

of linoleum, vinyl composition tile, solid vinyl tile, conductive tile,

vinyl and rubber sheet products is the specialized work of the floorlayer.

Using the skills learned at the Carpenter apprentice school, floorlayers

scribe, cut, fit, layout and install the many types of flooring materials

according to the specifications of the design professional. Installing

a floor may include installing various kinds of underlayment to ensure

a smooth and level surface for the finished floor. Installing flooring

also requires matching intricate patterns and designs at the floor covering’s

seams. Flooring tradesmen need to know how to heat weld a floor seam,

they need to know how to match carpeting patterns as well as how to create

specialized patterns and inset logos and designs.

The

installation of carpeting, hardwood flooring and resilient flooring made

of linoleum, vinyl composition tile, solid vinyl tile, conductive tile,

vinyl and rubber sheet products is the specialized work of the floorlayer.

Using the skills learned at the Carpenter apprentice school, floorlayers

scribe, cut, fit, layout and install the many types of flooring materials

according to the specifications of the design professional. Installing

a floor may include installing various kinds of underlayment to ensure

a smooth and level surface for the finished floor. Installing flooring

also requires matching intricate patterns and designs at the floor covering’s

seams. Flooring tradesmen need to know how to heat weld a floor seam,

they need to know how to match carpeting patterns as well as how to create

specialized patterns and inset logos and designs.

Special

floor installation processes are used in areas such as hospital operating

rooms or clean rooms. Sheet vinyl must be “flash-coved” up a portion of

the wall using heat-welded seams to create a monolithic seamless homogeneous

floor that can be flooded for cleaning. Using flash coving, the floor

curves into the wall and eliminates the difficult to clean angle at the

standard wall and floor junction. Flash coving is just one of several

special applications that requires much skill and practice from the floorlayer.

Special

floor installation processes are used in areas such as hospital operating

rooms or clean rooms. Sheet vinyl must be “flash-coved” up a portion of

the wall using heat-welded seams to create a monolithic seamless homogeneous

floor that can be flooded for cleaning. Using flash coving, the floor

curves into the wall and eliminates the difficult to clean angle at the

standard wall and floor junction. Flash coving is just one of several

special applications that requires much skill and practice from the floorlayer.

The resilient floor trades

often have an aggressive building schedule. All other structures in the

construction of a project including walls, ceilings, partitions and fixtures

must be completed before the floor layers can begin their work. Floor

layers perform many intricate tasks under challenging deadlines. The resilient

floor tradesmen are often the last group of tradesmen in a building before

it is turned over to the owner for occupancy. Flooring contributes to

a major portion of the image and mood created when entering a building

and serves to be a unifying element in the overall design of a building’s

interior. Consequently, the flooring trade involves many precision jobs

that must be done with care and attention to detail. Apprentices complete

a four-year program that includes blueprint reading, carpet, tile and

resilient material skills.

Back to Top

Wall

and Ceiling Laborers are a vital link in the construction process. Laborers

work closely with carpenters, drywall installers, plasterers and others

in the wall and ceiling trades. Wall and ceiling laborers may be plaster

tenders, material handlers, mortar mixers or trainees. Laborers are not

only responsible for materials handling but for properly and accurately

mixing plaster, drywall compounds, spray-applied fireproofing, and other

materials.

Wall

and Ceiling Laborers are a vital link in the construction process. Laborers

work closely with carpenters, drywall installers, plasterers and others

in the wall and ceiling trades. Wall and ceiling laborers may be plaster

tenders, material handlers, mortar mixers or trainees. Laborers are not

only responsible for materials handling but for properly and accurately

mixing plaster, drywall compounds, spray-applied fireproofing, and other

materials.

Damage control and safety are primary concerns of the material handlers on the construction site. They need to know how to move material from the drop off site through buildings that are undergoing renovations or under construction. Material handlers have many logistical challenges in occupied buildings. They must consider the safety of those continuing to do business and convey materials with out damaging existing structures.

Laborers

also assemble, move and remove scaffolding from the work site. As walls

and ceilings are being constructed, excess material and debris must be

removed from the site to promote safety and provide a clean work area.

Laborers

also assemble, move and remove scaffolding from the work site. As walls

and ceilings are being constructed, excess material and debris must be

removed from the site to promote safety and provide a clean work area.

Knowledge of materials, site

safety management, proper material mixing and scaffolding building according

to MIOHSA standards are taught in an apprentice program at the Plasterers’

school. Wall and ceiling laborers may upgrade their laborer skills by

acquiring further training in material handling equipment or they may

chose to enhance their skills by attending one of the apprentice schools

for carpentry, plaster, or drywall training.

Back to Top

Carpentry School

The

Carpentry School, established in 1941 is an apprentice training program

run in cooperation with labor and management. The carpentry school is

funded by the contractors that sponsor and employ carpenter apprentices

during their four-year stay at the school. Apprentices pay a nominal fee

for tuition. A mandatory 8,000 hours of on the job training hours are

required for completion. The school is certified by the Bureau of Apprentice

Training and the apprentices receive certificates from both B.A.T. and

the United Brotherhood of Carpenters and Joiners of America. All instructors

at the school have worked in the field for at least 10 years and have

completed the four-year program offered by the school.

The

Carpentry School, established in 1941 is an apprentice training program

run in cooperation with labor and management. The carpentry school is

funded by the contractors that sponsor and employ carpenter apprentices

during their four-year stay at the school. Apprentices pay a nominal fee

for tuition. A mandatory 8,000 hours of on the job training hours are

required for completion. The school is certified by the Bureau of Apprentice

Training and the apprentices receive certificates from both B.A.T. and

the United Brotherhood of Carpenters and Joiners of America. All instructors

at the school have worked in the field for at least 10 years and have

completed the four-year program offered by the school.

A high school diploma or GED is required prior to completion of this apprenticeship training program. Carpenter apprentices are required to attend classes at the Detroit Carpentry Apprenticeship school every two weeks. Subjects taught include carpentry mathematics, roof framing, measuring tools, power equipment and blueprint reading. Carpenter apprentices learn to construct partitions, install interior trim, build stairs and install ceilings and metal framing.

Guest speakers from MIOSHA, CPR instructors, labor and management help prepare apprentices for work on the job site. General carpentry skills are taught and apprentices may choose to specialize in such areas as floor laying, millwork, lathing and commercial or residential interior systems.

While in this program, apprentices are indentured to the school and the joint apprenticeship committee. Apprentices earn a percentage of the journeyman scale wage while they learn. The availability of work determines whether an apprentice will stay with the same contractor through all four years. Applications are taken at the school offices located in Ferndale every Wednesday. Apprentices are matched up with contractors by the school, but an individual contractor may bring a student into the program as well.

Prior to admittance to the program each apprentice is given a series of assessment tests in reading and mathematics. Additionally, applicants must pass a mandatory drug-testing.

The apprenticeship school, through its standards and practices, ensures that all journeymen carpenters receive a standardized education that meets the requirements of the school and the union. This aids the industry as a whole, by maintaining consistency and high quality workmanship. The school also provides continuing education classes for journeymen carpenters in safety, CPR and supplementary training on new products and techniques used in the field.

Each year a statewide competition is held and the winner is awarded the honor of the “Best Carpenter in Michigan.” The categories of the competition are metal framing and interior systems, wood framing, floor laying and millwright work. The competition consists of a four-hour written test and an eight-hour hands-on project. Winners and participants reflect the pride these trades-men take in their industry.

The Carpenter school provides an opportunity for high school students to try their hand at the trade and get a head start in an apprenticeship program while still in high school. High school juniors and seniors may participate in a school-to-work program during summer vacation. After graduation from high school this school-to-work program credits 6 months of the apprentice program.

Career options for carpenters do not stop at the journeyman level. A journeyman carpenter may consider advancement to a career in construction management. This could mean a position as a foreman, site supervisor or ownership of his or her own construction company.

Drywall Finishers Apprentice Program

Drywall

finishing apprentices learn such techniques as fire-taping, sanding, and

screw and nail spotting, applications of joint treatment materials with

hand tools, including the hawk and trowel as well as the pan and knife.

Finishing with tools, such as the bazooka and the banjo, and the use of

box and corner tools are an integral part of their training. All phases

of drywall finishing, wet and dry sanding, and proper use of special compounds

are covered. Blueprint reading and mastery of the architect’s scale, along

with mathematics needed for the ordering of materials and meeting building

scheduling requirements, are included in the drywall finishing apprentice’s

training. The care and maintenance of automatic taping tools and power

actuated tools, safety and good work practices are strongly stressed.

Scaffolding and ladder training is also a part of the safety training

of the drywall finishing apprentice. A safety course developed especially

for tapers includes CPR instruction and first aid on the job.

Drywall

finishing apprentices learn such techniques as fire-taping, sanding, and

screw and nail spotting, applications of joint treatment materials with

hand tools, including the hawk and trowel as well as the pan and knife.

Finishing with tools, such as the bazooka and the banjo, and the use of

box and corner tools are an integral part of their training. All phases

of drywall finishing, wet and dry sanding, and proper use of special compounds

are covered. Blueprint reading and mastery of the architect’s scale, along

with mathematics needed for the ordering of materials and meeting building

scheduling requirements, are included in the drywall finishing apprentice’s

training. The care and maintenance of automatic taping tools and power

actuated tools, safety and good work practices are strongly stressed.

Scaffolding and ladder training is also a part of the safety training

of the drywall finishing apprentice. A safety course developed especially

for tapers includes CPR instruction and first aid on the job.

Drywall finishing apprentices learn on the job under the watchful eye of the journeymen drywall tradesmen and attend classes at the Drywall Finishers’ School twice a month. Upon satisfactory completion of 4,000 hours or 2 years of training at the drywall finishers’ apprenticeship school in Hazel Park, apprentices are awarded a journeymen status in the Drywall Finishing Trade.

Plasterers Apprentice Program

Apprentices

learn on the job and attend a three-year apprenticeship at the Plasterer

Apprentice School at the Michigan Labor Training Center in Wayne, Michigan.

Apprentices are required to pass a general aptitude test, participate

in an oral interview and pass a drug test to be accepted. While at the

school apprentices learn to develop good mechanical abilities while mastering

the handling, mixing and skilled application of such materials as plaster

and cement finishes. Apprentices also learn such specialized skills as

the design and fabrication of decorative molds used for casting stylized

design details. Safety is also highly emphasized in specialized equipment

and scaffolding safety procedures.

Apprentices

learn on the job and attend a three-year apprenticeship at the Plasterer

Apprentice School at the Michigan Labor Training Center in Wayne, Michigan.

Apprentices are required to pass a general aptitude test, participate

in an oral interview and pass a drug test to be accepted. While at the

school apprentices learn to develop good mechanical abilities while mastering

the handling, mixing and skilled application of such materials as plaster

and cement finishes. Apprentices also learn such specialized skills as

the design and fabrication of decorative molds used for casting stylized

design details. Safety is also highly emphasized in specialized equipment

and scaffolding safety procedures.

Back to Top

![]()

ARCHITECTURAL

CONTRACTORS TRADE ASSOCIATION OF MICHIGAN

2524 Harte Drive

Brighton, MI 48114

(810) 225-3327

e-mail: info@actmich.org